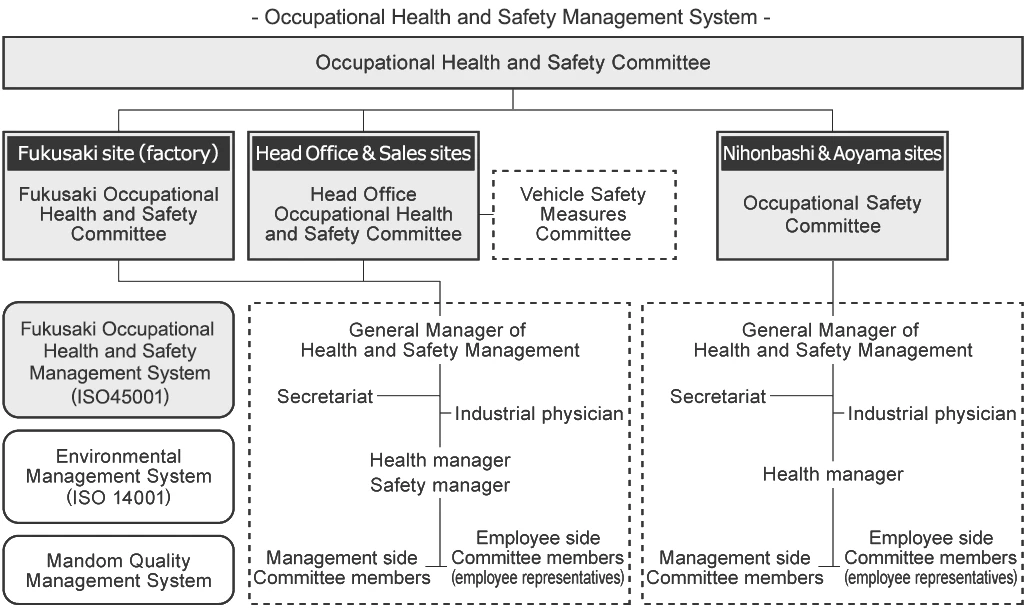

Occupational Health and Safety

Establishment of an Occupational Health and Safety Committee

At Mandom, we strive every day to ensure the safety and health of employees in the workplace, and, beyond that, to promote the creation of a pleasant workplace environment. We do this by promoting comprehensive, systematic measures to prevent occupational accidents based on the Labor Standards Act, Industrial Safety and Health Act, and occupational safety and health regulations. To promote efforts to realize our objectives, an Occupational Health and Safety Committee has been established, chaired by the Supervising Executive Officer of the Human Resources Division. This committee is working to strengthen our occupational health and safety management system.

Creating a Healthy and Safe Workplace Environment at Our Factory

Mandom's Fukusaki Factory has acquired ISO45001 certification, a widely used international standard for

occupational health and safety management systems, and we are working hard to create a healthy and safe

workplace environment.

ISO45001 international standard aims to proactively prevent labor accidents,

mitigate disasters and eliminate health hazard risks by clarifying the occupational health and safety

policies of organizations, and conducting PDCA (Plan-Do-Check-Action) management using an "established

evaluation system."

Going forward we will continue working hard to ensure that operations at Mandom's Fukusaki Factory take into account consumers, society, the environment, and employees. This will be achieved by striving for continuous operation and synergistic effects, and implementing three management systems: an occupational health and safety management system; an environmental management system (ISO 14001 international standard) which aims to simultaneously achieve management together with reduction in environmental risk and contribution to the environment based on the idea of sustainability; and the Mandom Quality Management System for raising the quality of the company, products, and services, and achieving true customer satisfaction.

Group training at the Fukusaki Factory on occupational health and safety and environmental protection

Mental health measures

Since FY2011 we have utilized the Employee Assistance Program (EAP) specialist HOKENDOHJINSHA Inc. to provide a toll-free support hotline for employees and their families that allows individuals to speak with an outside counselor about their troubles. We also bought group long-term disability income indemnity (GLTD) insurance, and in May 2011 set up regulations pertaining to employees taking leave to cover how employees are treated when they are on leave and after they return to the workplace. In these and other ways we are strengthening our mental health measures. Since FY2012 we have been asking all employees to take a stress check and following up with private consultations if necessary.

Mandom Safe Driving Courses

Within the Mandom Group in Japan, about 500 vehicles are on the roads per day across the country, including

both company vehicles and vehicles used for commuting to work.

We set up a Vehicle Safety Measures

Committee to carry out ongoing, in-house educational activities cooperated by expert on road traffic safety to

prevent road accidents.

Based on an understanding that we are still insufficiently prepared for risk, we will continue striving

to prevent road accidents.

Safety measures at head office building

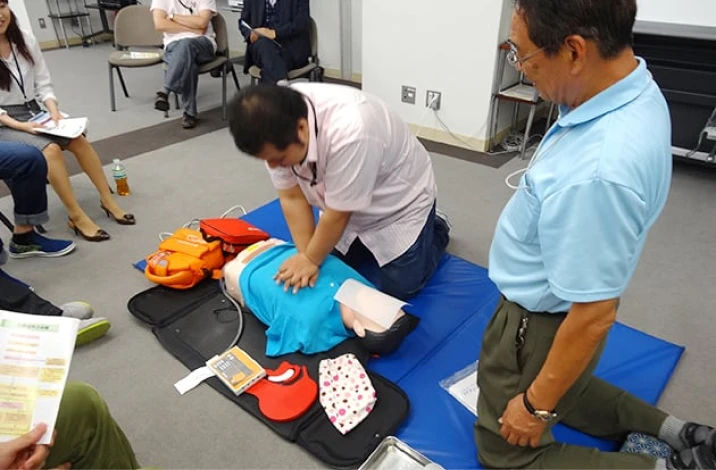

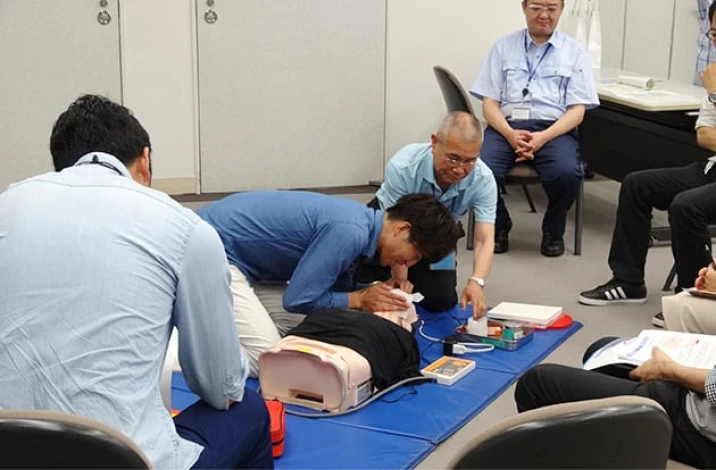

Mandom is engaged in various initiatives to help prevent casualties from natural disasters. Every year, firefighters from Osaka's Chuo Fire Station visit the head office building to conduct a variety of drills to prepare Mandom's employees for a potential disaster such as an earthquake or fire, covering topics such as alerting others when a fire is discovered, initial efforts to put out a fire, using a fire extinguisher, evacuation, and rescue. We are also engaged in a basic course in life-saving and provide emergency skills training.

Firefighting drills at the head office

Lecture on emergency life-saving techniques

Regarding Fire Accident at Consolidated Subsidiary, PT Mandom Indonesia Tbk

Mandom Corporation would like to offer prayers and condolences to the bereaved families of the local employees who lost their lives due to the fire that occurred at our consolidated subsidiary, PT Mandom Indonesia Tbk on July 10, 2015. We hope that the souls of the deceased will rest in peace and that the injured local staff makes swift recovery. We are deeply sorry for the inconveniences and concerns that we have caused many of our stakeholders and neighboring communities.

In order to identify the cause of the accident and hammer out preventive measures, Mandom Corporation

visited the site of the accident twice in September and October. In November 2015 after the cordon was

lifted by the local police, Mandom set up "Accident Investigation Panel" composed of five external

academic and investigation experts.

Through three panel sessions, analysis and simulation of the cause of the accident was performed

based on various data supplied by Mandom. The Panel analyzed the cause and compiled the final report that

proposes preventive measures against recurrence.

Mandom will use the abovementioned report published by Accident Investigation Panel to implement activities aimed at preventing recurrence of the accident. Our efforts to provide relief to the victims and bereaved families will continue as part of our attempts to overcome the CSR issues.

Establishment of Mandom Group Safety and Reliability Day

In solemn recognition of the seriousness of the accident which occurred on July 10, 2015, we will refer to

the measures to prevent recurrence advocated in the aforementioned final report by the Accident

Investigation and Response Committee, and make continual efforts to ensure safety and reliability in our

business activities so that this sort of accident never recurs in the future.

Based on the idea of putting safety first, we are working to prevent recurrence in all our projects

and at all of our manufacturing sites, but in order to take this accident as a major lesson and prevent any

fading of its memory, we have established July 10 of every year as the Safety and Reliability Day of the

Mandom Group. On this day, we will offer our wishes in memoriam of the victims of the accident, and

diligently review safety and reliability throughout our group. It is not just machinery at manufacturing

sites or workplaces handling hazardous materials that may pose a risk to safety and reliability. Safety

problems may be present even at non-manufacturing workplaces such as offices or sales facilities. Therefore,

on Safety and Reliability Day, all of our employees will observe a moment of silence, and during that week,

each workplace will consider and discuss risks to safety and reliability. The content of these activities

will be planned by the Total Risk Management Committee, and then applied to organizations relating to each

issue or countermeasure.