Formation of a Recycling-Oriented Society

Reducing Waste

Since October 2003, the Fukusaki Factory has achieved "zero emissions," defined as a 99% or higher resource

recovery rate for industrial waste.

Since FY2019, all business sites in Japan have also achieved zero emissions, and this status has been

maintained continuously. An example of recycling is the pelletizing* of plastics. We also strive to reduce

waste generation by improving production processes.

To encourage waste reduction and recycling at our

head office building, we conduct annual environmental awareness seminars relating to such topics as

environmental problems, and rules for proper waste classification and disposal for new employees and

individuals who have transferred to the head office building. In addition, we encourage thorough use of

waste sorting and shredders , as the city of Osaka passed a law in 2013 requiring 100% of paper to be

recycled.

In addition, in order to deepen our knowledge of the transition to a recycling-based society and to strengthen our efforts for a sustainable global environment, we participated in the MEGURU BOX Project, a demonstration experiment to collect used plastic, which was implemented from July 2021 by the Kyushu Circular Economy Partnership (secretariat companies: AMITA HOLDINGS CO., LTD. and NEC Solutions Innovator, Ltd.) to optimize resource cycle in Kyusyu region and create business contributing to a sustainable society.

Waste Resource Recovery Initiatives

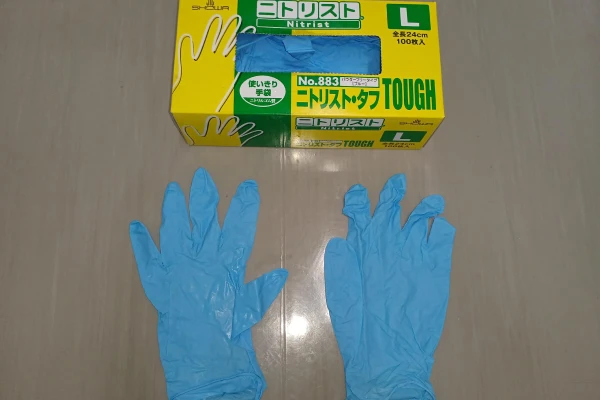

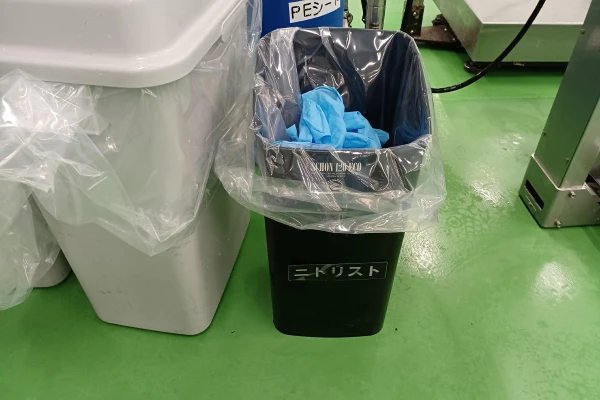

At the Fukusaki Factory, we conduct improvement activities every year with an awareness of waste resource recovery within the factory. As an example of these improvement activities, packaging paper used as raw material for nonwoven fabric deliveries, which used to be treated as waste, is now collected by an intermediate processing contractor and recycled as recycled paper. In addition, nitrile gloves, which were collected by a contractor after being sorted and collected post-use within the factory, are recycled as raw materials for roadbed materials and sand cushioning. We are committed to further improvements and initiatives toward a recycling-oriented society.

Example of packaging paper initiative

Example of nitrile glove initiative

Efficient Water Use

We deeply recognize that water is an essential element of our business activities and is also one of the

most precious resources on earth. Therefore, we pay particular attention to the use of water in our business

activities and actively promote the reuse of water in accordance with the Environmental Policies to save

water resources and achieve a circular economy.

Our business sites do not use ground water. Our production sites do not have a high water risk and minimize

the impact of potential natural disasters on water resources. We have also set a Group-wide target regarding

water resources and monitor its achievement.

Target

To reduce water withdrawal (per unit of production volume) at our three production sites by at least 3%

compared to FY2021 by FY2027

Water-saving efforts at the Fukusaki Factory

At the Fukusaki Factory, we are working to reduce water use by regularly calling upon each department to

save water, and reviewing methods of cleaning production equipment, piping and other facilities. We have

also introduced a chiller* to reduce the use of industrial water.

At the head office building we use

water-saving equipment that controls water flow and low-flush toilets to reduce water use.