Global Warming Prevention

Promoting measures toward a carbon-free society

Initiatives related to climate change (disclosure based on TCFD*1 recommendations)

Since the Industrial Revolution, especially since the 20th century when the population increased

significantly, it has been acknowledged that carbon dioxide emissions have greatly increased.

This

increase in carbon dioxide emissions is contributing significantly to climate change, including global

warming. As the Intergovernmental Panel on Climate Change (IPCC) notes, in its Sixth Assessment Report

(Synthesis Report) released in March 2023, that human activities have been causing global warming, we in the

Mandom Group recognize that the implementation of concrete measures against climate change is an urgent

issue that the world should work on together to realize a sustainable society.

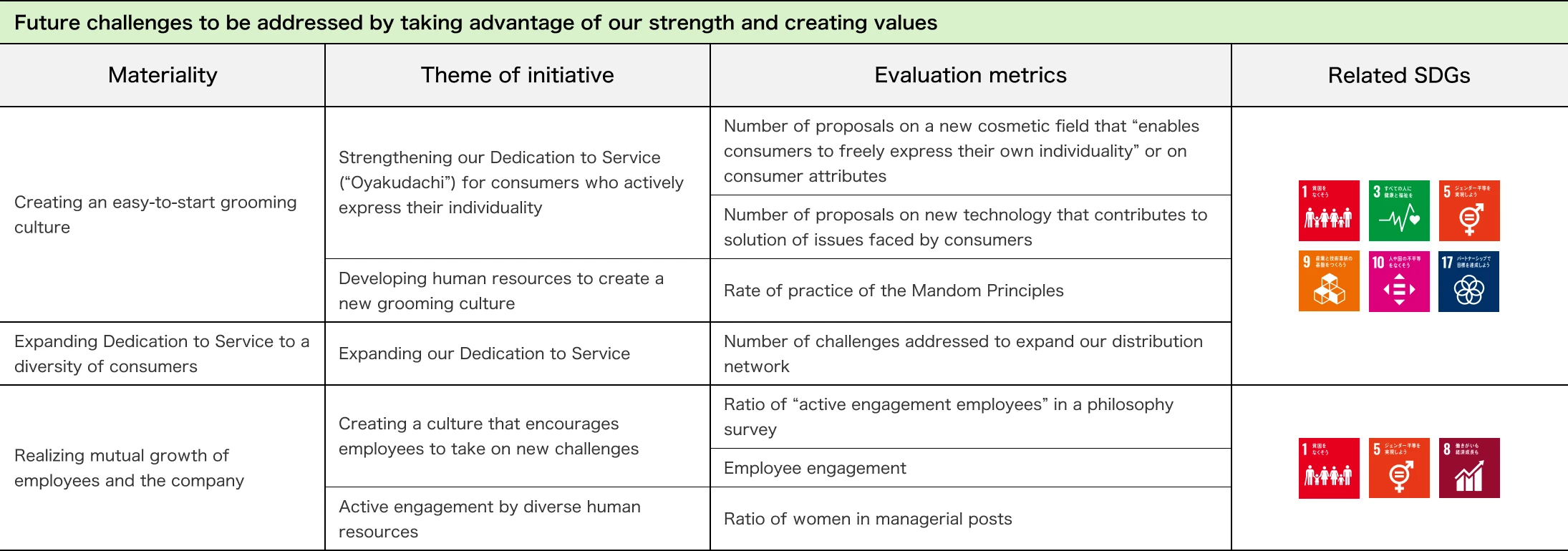

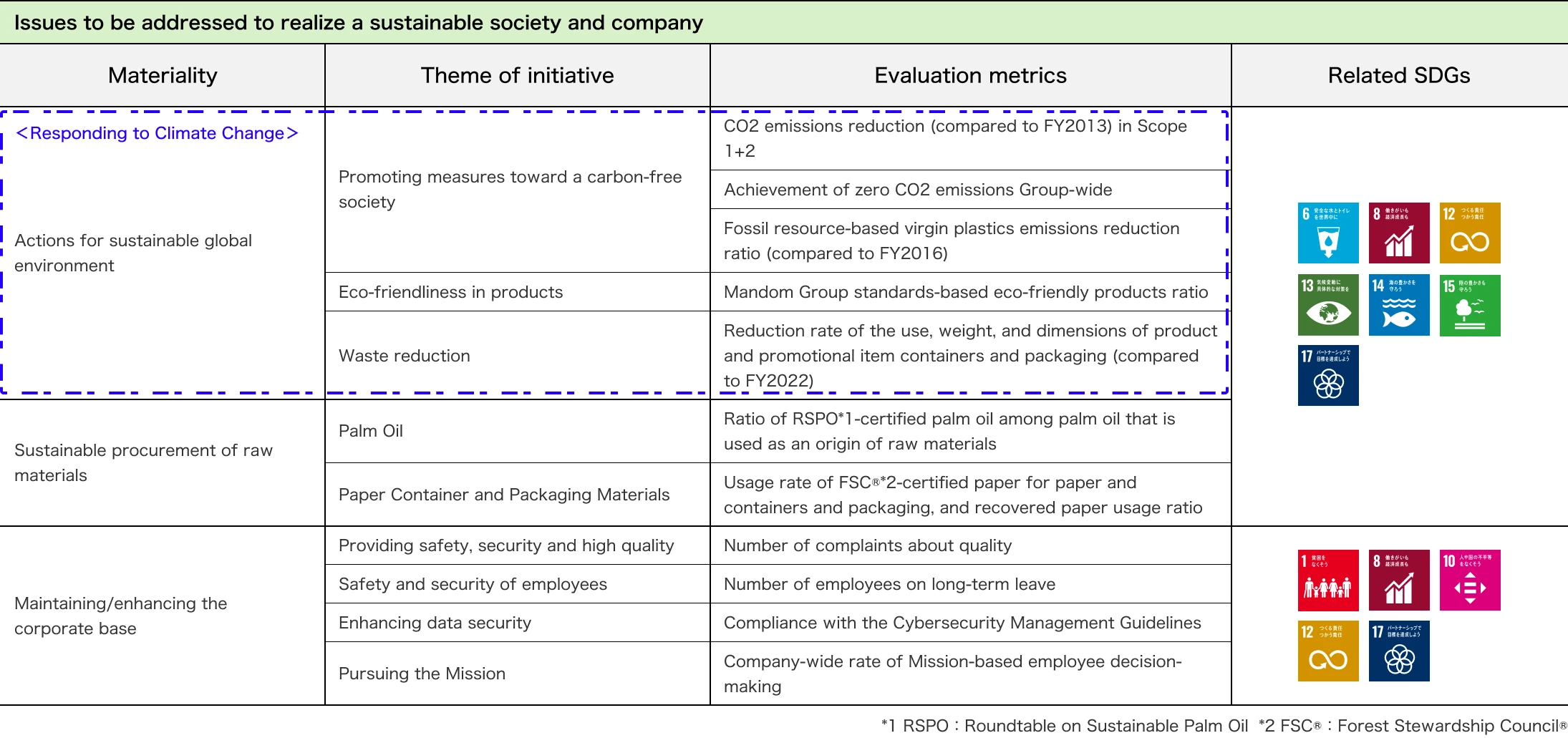

Against the backdrop of the fact that addressing climate change is a social issue and that implementing measures against climate change is a social need, we regard "co-existence, mutual growth, and mutual creation with global society," which is included in our corporate philosophy, as the sustainability of the Mandom Group itself. In 2021, we formulated sustainability policies with sustainable management for solving social and environmental issues as their foundation and identified key issues (materiality) in sustainability. Our aim is to evolve our Dedication to Service (Oyakudachi) and create corporate value through the initiatives of our core business. As part of specific efforts to promote the initiatives, we set key performance indicators (KPIs) for each materiality*2 in 2023.

The corporate slogan "BE ANYTHING, BE EVERYTHING" is also our ESG slogan.As a "human-oriented" company, we devised this slogan to be relevant to all employees; in As a "human-oriented" company, we devised this slogan to be relevant to all employees; in a society where social issues-such as environmental issues, globalization, diversity, and identity-are becoming increasingly diverse and complex, and where it is difficult to resolve the issues faced by consumers, the slogan represents Mandom's desire to be dedicated to service and to help realize a sustainable and affluent society where people can enjoy expressing their true selves, live healthy and positive lives, and continue to challenge themselves to express their true selves, rather than giving up or sacrificing one for the other, in a so-called trade-off relationship. In particular, in response to climate change, we expressed our support for the TCFD in June 2022, as a good corporate citizen living socially with the dynamism of the times, and in order to be more effective in evolving our Dedication to Service and creating corporate value through our core business. We will use the TCFD proposal framework to further strengthen our governance on climate change. In addition, by reference to scenarios*3 disclosed in various initiatives, including the IPCC Sixth Assessment Report, we will analyze and identify the risks and opportunities arising from climate change, and assess their impacts on our financial statements.

AR6 Synthesis Report: Climate Change 2023: IPCC

World Energy Outlook(WEO) 2022 International Energy Agency (IEA) [PDF data]

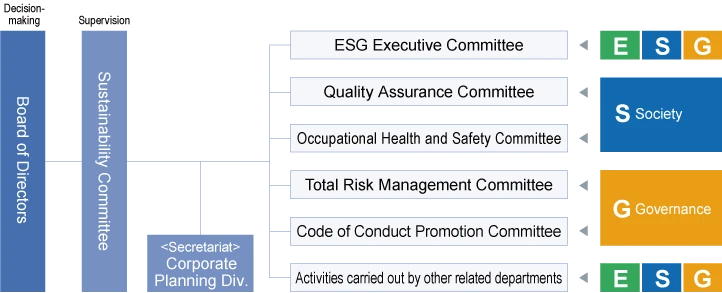

◆Governance

Our Group has established a Sustainability Committee chaired by the President Executive Officer to promote sustainability initiatives that aim to address both increasingly diverse and complex social issues and consumer needs. Under the Sustainability Committee, several subcommittees have been formed to identify potential risks and opportunities from environmental, social, and governance (ESG) perspectives and to facilitate implementation by the relevant operational departments. The Sustainability Committee exercises overall management of the entire process, from monitoring risks and opportunities identified by each subcommittee to overseeing the initiatives carried out by the respective departments to address them.

<Medium- to long-term targets for key issues (materiality) in sustainability>

Click the following table to enlarge.

<Promotion System>

◆Strategy (Analysis of Opportunities and Risks)

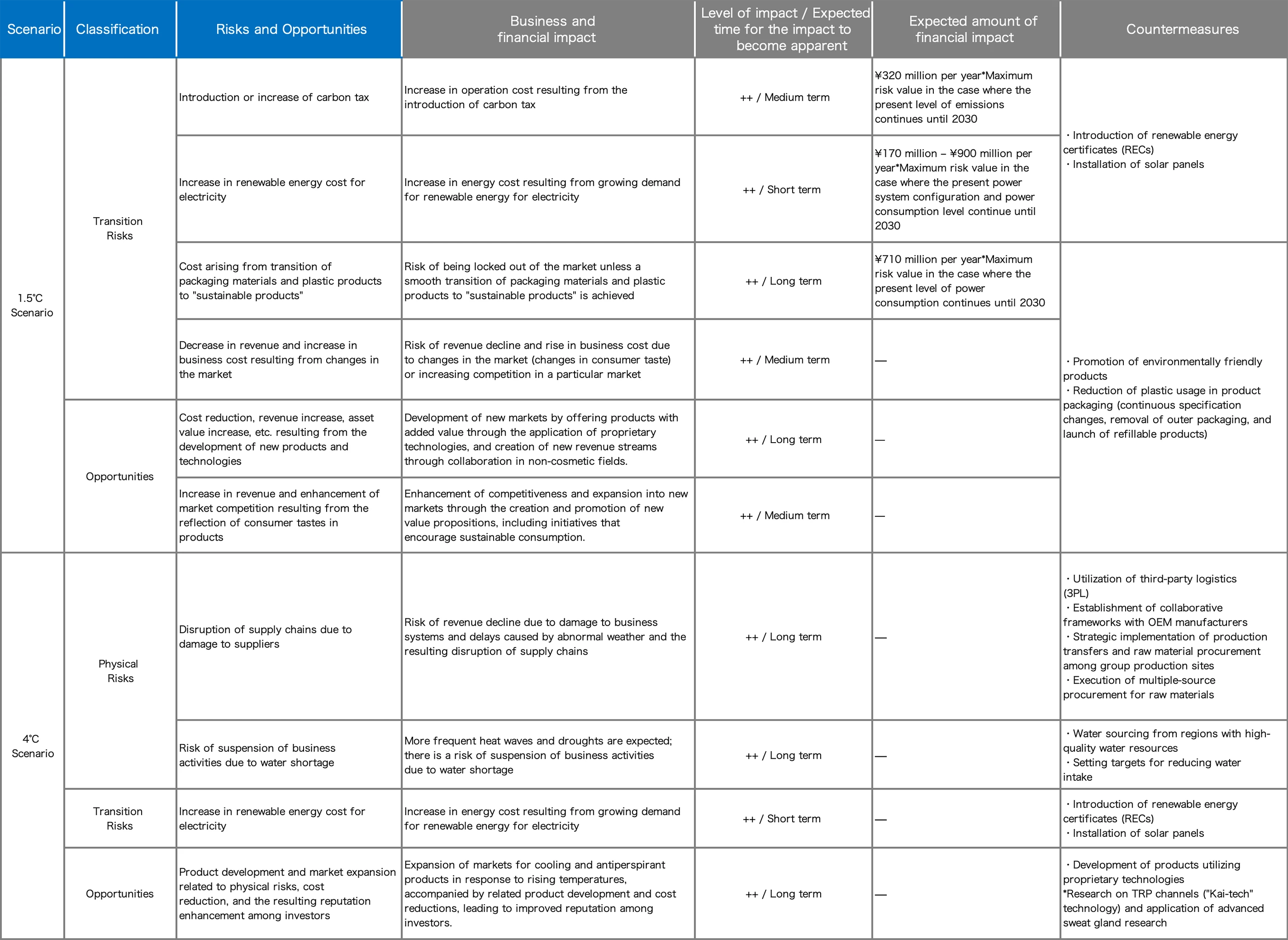

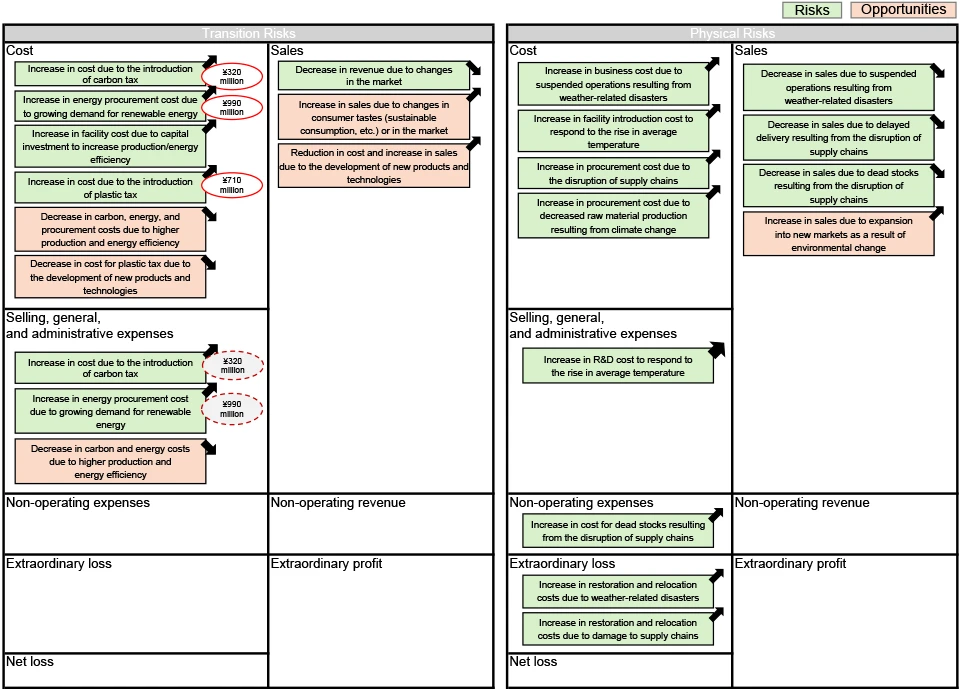

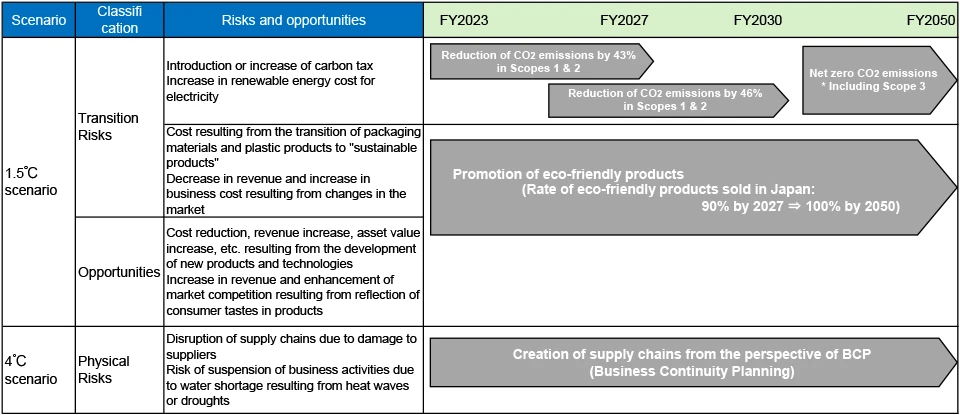

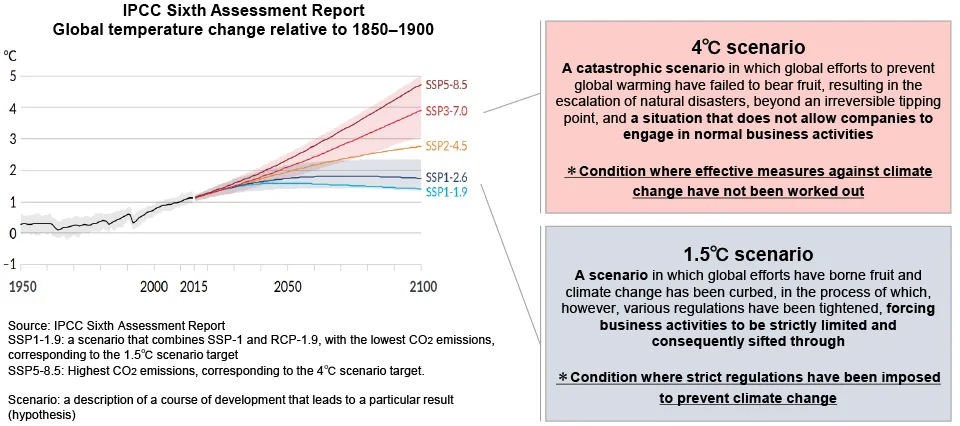

With regard to climate change issues, various scenarios can be considered depending on the status of measures to prevent global warming. Our Group refers to the "4℃" scenario and the "1.5℃" scenario regarding the typical average temperature with reference to various materials, and examine both physical risks and transition risks in business management.

The 1.5℃ scenario predicts that technological innovations and more stringent regulations for suppressing global warming will progress, thereby changing society. The 4℃ scenario predicts that extreme heat and severe storms will occur if global warming is not sufficiently contained. Regarding the impact of these scenarios on our Dedication to Service (Oyakudachi) through products that are in our business domain, we will analyze risks and opportunities as well as the resulting impacts on our business model and value chain, and actively engage in initiatives and information disclosure.

| Physical risks | Transition risks |

|---|---|

|

|

<Climate Change-related Risks and Opportunities>

Click the following table to enlarge.

[Expected time for the impact to become apparent] short term: 0-1 year; medium term: 3-5 years; long term: 10 years or more

[Expected level of impact] ++: significant impact, +: some impact, −: minor or virtually no impact

◆Risk Management

Under the Sustainability Committee, relevant committees examine the impact of climate-related opportunities

and risks on our business activities, grasp the situation of the entire group, consider how to respond to the

opportunities and risks, and manage the progress on each key issue (materiality) and target through

deliberations and approval by the Sustainability Committee, as well as through reports to the Management

Council and the Board of Directors.

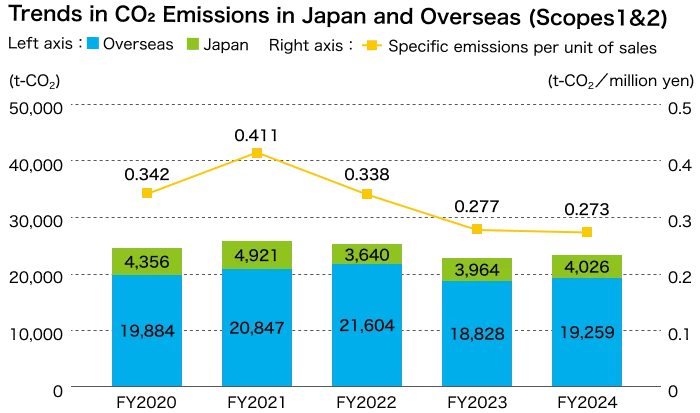

For actual CO2 emissions, we calculate the amount of CO2 emissions derived from group-wide energy and electric power consumption (Scopes 1 & 2) and emissions

produced throughout the value chain in Japan (Scope 3) once a year, to manage progress toward the targets.*4

In particular, we recognize that our CO2 emissions are largely attributable to electric power

consumption in Scope 2 and the procurement of raw materials and the use of products in Scope 3. We approach

the issue of reducing CO2

emissions in terms of both risks and opportunities in our business activities, set medium- to long-term

targets, and concentrate our efforts on switching to renewable energy sources for the electricity used for our

business activities and developing eco-friendly products. For CO2 emissions produced throughout the

value chain, we will promote efforts to make calculations and grasp the situation on an entire-group basis.

<CO2 Emissions Produced in Business Activities>

◆Metrics & Targets

Our Group is proceeding with our efforts to grasp GHG emissions (Scopes 1, 2 & 3) in order to realize a sustainable society. Believing it was necessary to further accelerate our efforts, in addition to the long-term targets that had been formulated, we newly formulated medium-term targets in December 2021 to achieve those long-term targets. We also developed a road map concerning risks and opportunities, based on the scenario analysis conducted in 2022, and we are currently promoting its implementation as a group-wide initiative.

○Reducing GHG emissions in the group

- Long-term goal

Aiming to achieve zero CO2 emissions Group-wide in 2050. -

Medium-term goal

Aiming to reduce CO2 emissions in Scope 1+2 in Japan and Overseas by 46% or more compared to fiscal 2013 by fiscal 2030.

Aiming to reduceCO2 emissions in Scope 1+2 in Japan and Overseas by 43% or more compared to fiscal 2013 by fiscal 2027.

<Related objectives>:Environmental considerations in products

-

Long-term goal

By 2050, we aim to turn 100% of products marketed by the Mandom Group into eco-friendly products. -

Medium-term goal

By 2027, we aim to turn 90% of Mandom products marketed in Japan into eco-friendly products.

<Road Map for Initiatives Related to Risks and Opportunities>

Click the following table to enlarge.

<Status of Progress>

In FY 2024, additional solar panels were installed at the Fukusaki Factory. However, due to increased

production volumes in both Japan and Indonesia, CO2 emissions (Scope 1 + 2) in Japan and overseas

increased by 2.2% year-on-year.

Regarding our efforts to make our products environmentally friendly, we are expanding our range of

eco-friendly products, and as of the end of FY 2024, 60.5% of Mandom products sold in Japan were

environmentally friendly. In addition, as part of efforts to respond to changes in consumer value in the

market due to rising outside temperatures associated with climate change, we are working on the roll-out of

products to which our unique "Kai-tech technology"*5 is applied (e.g., GATSBY Space Shower Paper for the

scalp/body and Mandom Happy Deo Body Sheet Super Refreshing/Extra Cool types). Furthermore, we are also

engaging in the application of advanced sweat gland research.

Kai-tech technology: Mandom's unique technology developed to pursue more comfortable feeling in use by utilizing its knowledge related to transient receptor potential (TRP) channels, which are sensors in skin cells

Calculating greenhouse gas emissions for the entire value chain

Mandom is helping the move toward a carbon-free society. We believe that reducing greenhouse gas emissions is vital throughout the value chain, from the procurement of materials to the manufacture of products, and then on to their sale, use, and disposal. As such, since FY2018, we have been calculating the greenhouse gas emissions produced throughout the value chain based on the Scope 3 Standard established by the GHG Protocol.

Scope of calculations: Japan

Period of calculations: April 2024 - March 2025

Our calculations show that more than 90% of greenhouse gas emissions fall under Scope 3 and we were able to

see that emissions were particularly large in Category 1 (Purchased goods and services) and Category 11 (Use

of sold products).

In addition to improving the accuracy of future calculations, we will strive to

reduce our environmental impact throughout the value chain, such as by developing environmentally friendly

products that can help reduce emissions in the categories detailed above.

Fukusaki Factory Systems

Power Monitoring System and Effective Use of Power

At the Fukusaki Factory, the power consumption data taken from the power monitoring system is shared at a

monthly supervisors' meeting by the plant manager and used in the various sections of the factory to develop

energy-saving measures.

A switch was made to thermal energy for nighttime power for the air

conditioning and refrigeration system, and an ice thermal storage system was adopted for daytime for the

most effective use of power. We are also upgrading airconditioning equipment, and changing lighting to LEDs.

Power monitoring system

New Boilers and Initiatives to Reduce the Carbon Footprint of Boiler Fuel

When relocating the boilers at the Fukusaki Factory, we decided to install new boilers, changing our kerosene-fired units into LPG-fired ones. The new set-up began operations in November 2018 and will lead to a significant reduction of the boilers' environmental impact by reducing carbon dioxide emissions by around 15 percent, improving combustion efficiency, and slashing emissions of pollutants like sulfur oxides and nitrogen oxides. Other benefits will include lower administration costs, and moving forward, we are also eager to boost the efficacy of our energy-efficiency initiatives by providing visual measures of steam use.

Office Systems

Furthermore, we are engaged in an ongoing shift to LED lighting and high-efficiency transformers. We take many measures to reduce power consumption in the peak summer and winter seasons from July to September and December to March. We carefully control indoor temperatures, use air circulators that boost air conditioning efficiency, keep some lights off, use computers in energy-saving mode, and turn off or limit use of equipment that draws power.

Product Distribution

In truck transportation we strive to continue achieving close to a 100% load efficiency.

Using Renewable Energy: Solar panels installed at Fukusaki Factory and two factories in Indonesia

We are working to achieve carbon neutrality—net zero CO2 emissions—for the entire Group by FY2050. We regard the use of renewable electricity as one of the key approaches to realizing a decarbonized society. In September 2021, 1,728 solar panels were installed on the rooftop of a new production building completed at the Fukusaki Factory. In addition, 128 more panels were added in August 2024, enabling a total maximum in-house power generation capacity of 560 kW under sunny conditions. Moreover, we switched all electricity procured for our head office building to renewable electricity in April 2022.

Outside Japan, solar panels installed on the roofs of our two factories in Indonesia are in operation. Solar power generation commenced at Factory 1 (filling plant) in May 2023 and at Factory 2 (container manufacturing plant) in April 2023. A combined total of up to 1,100 kW of electricity is generated at the two factories when it is sunny.

Solar panels on the roof of a new production building

Solar panels on the roof of the factory

Solar panels on the roof of the factory